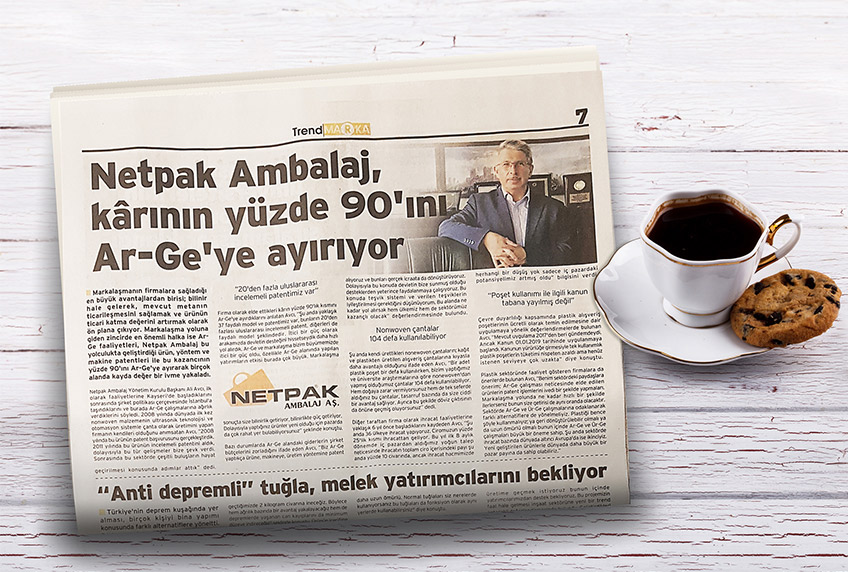

One of the biggest advantages of branding to companies; becoming known, it comes to the forefront as ensuring the commercialization of the existing commodity and increasing the commercial added value of the product. The most important link in the chain that leads to branding is R&D activities, Netpak Ambalaj gained a significant momentum in many areas by allocating 90 percent of its earnings to R&D with the product, method and machine patents it developed in this journey.

Netpak Ambalaj Chairman of the Board Ali Avcı said that they first started their activities in Kayseri, then they moved to Istanbul within the framework of company policy and focused on R&D studies here. Reminding that they were the first company in the world to manufacture nonwoven material as bags with ultrasonic technology and automation system in 2008, Avcı said, “We made a patent application for this product in 2008. We obtained a patented patent for this product in 2011, so such developments gave us enthusiasm. Afterwards, we took steps to implement various inventions in this sector.”

"WE HAVE MORE THAN 20 INTERNATIONAL EXAMINED PATENTS"

Explaining that they allocate 90 percent of their profits as a company to R&D, Avcı said, “Currently, we have about 37 utility models and patents, more than 20 of them are patents with international examination, and the others are utility models. If we felt the support of the state behind us as a driving force, we would have progressed faster. R&D and branding have been a driving force in our growth, especially the impact of investments made in the field of R&D is huge here. Branding ultimately brings you awareness, and awareness brings power. Therefore, since the products you make are new, you can easily find a place in the market.”

Expressing that in some cases the expenses in the field of R&D strain the company budgets, Avcı said, “We. As we do R&D, we obtain patents for the product, machine and production method and turn them into real practices. Therefore, we are trying to take advantage of the support provided by the state to us in this regard. In this regard, I think that the incentive system and incentives should be improved. The further we go in this area, the more profitable our country and our industry will be.”

NONWOVEN BAGS CAN BE USED 104 TIMES

Currently, the nonwoven bags they produce; Expressing that it is more advantageous than shopping bags made of paper and plastic, Avcı said, "While one plastic bag can be used once, the bags we have made from nonwoven can be used 104 times, according to university research. You do not harm the nature and these bags you buy in one go. "It also gives you a serious advantage in terms of savings. In this way, you also prevent foreign exchange output," he said.

On the other hand, Avcı, who noted that they started their export activities as a company 6 years ago, said, “Currently, we are exporting to 36 countries. 25 percent of our turnover comes from exports. As a result of the intense demand we received from the domestic market in the first 8 months of this year, the share of exports in total turnover is currently around 10 percent, but there is no decrease in our export volume, only our potential in the domestic market has increased.

"LAW REGARDING THE USE OF BAG IS NOT EXTENDED TO THE FLOOR"

Making evaluations about the paid plastic shopping bags within the scope of environmental awareness, Avcı said, “The current practice has been on the agenda since 2017. However, the Law started to be implemented on 01.01.2019. With the enactment of the law, the consumption of disposable plastic bags has decreased relatively, but it is still far from the desired level.” Avcı, who also made suggestions to companies operating in the plastics industry, said, “My suggestion to the stakeholders in the industry; Making the patent procedures of the products obtained as a result of the R&D work promptly. The faster you progress on the road to branding, the more it will yield you. We should focus on R&D and P&D studies in the sector and turn to different alternatives. I think we should use plastic like this; It must either be recyclable or have a long life, in which R&D and P&D studies are of great importance. Currently, we are the sixth in the world and the second in Europe in terms of exports in the sector. We can also have a larger market share in the world with newly developed products.

09.08.2021